It’s been close to a year since my last update, and many hours have been flown. I just got back from my condition inspection, and the good news is that the Velocity is flying better than it ever has. I’ve finally got the #5 cylinder temperature under control, and my critical squawks list is down to zero. The bad news is that getting there included going through a nose collapse. Yep… I finally had my first landing gear failure. More on that later. Outside of the repairs for that event, additional work done in the past year included:

- Replaced Engine Driven Fuel Pump

- Updated Landing Gear Retract Control System

- Replaced Emergency bypass valve

- Installed “Shark Fin” Cooling VGs

- Rebuilt Pilot Side door latch mechanism

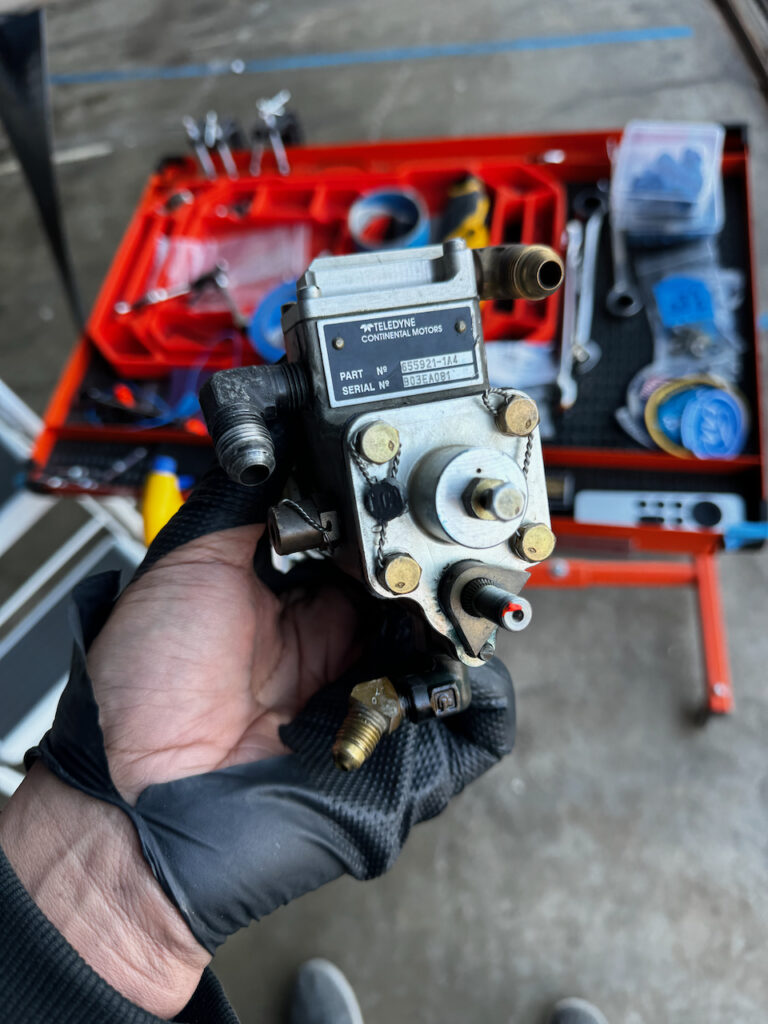

11/3/2023 - Engine Driven Fuel Pump Replacement

In the annual condition inspection, the main item we saw that needed immediate attention was a slight weeping of the engine driven fuel pump. I had previously replaced the electric fuel pump so it was good to get this one swapped out as well. It was a straight forward removal, and I sent it for overhaul. When it came back I was able to get it installed in a couple hours. Nothing major to report. Nice!

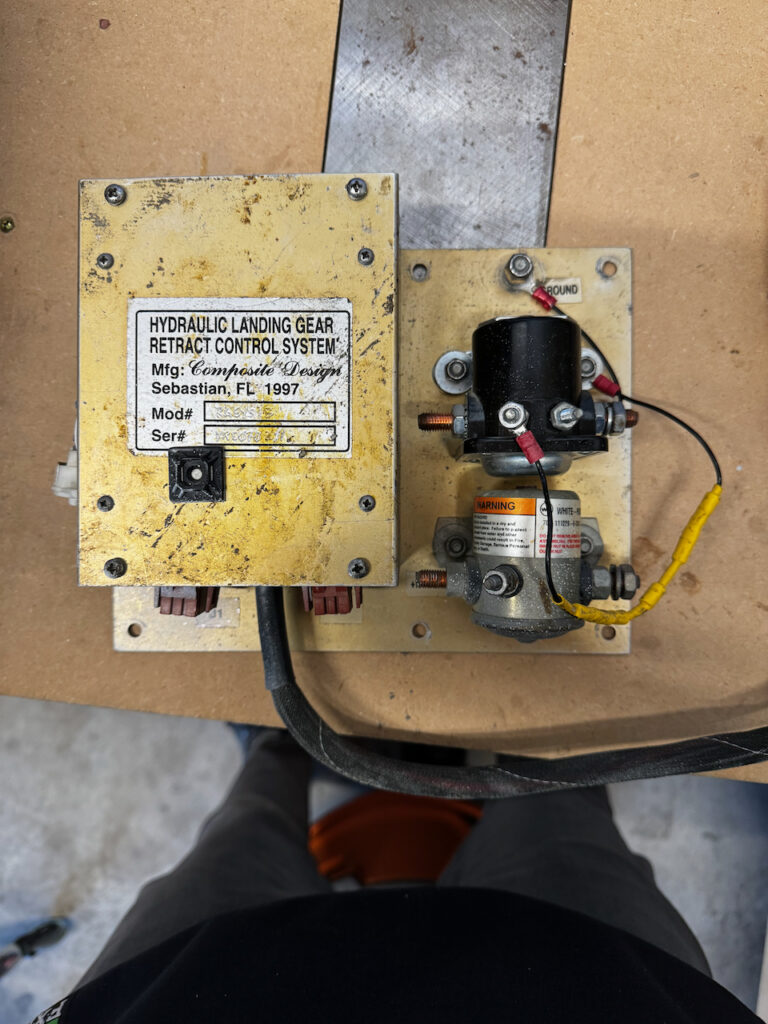

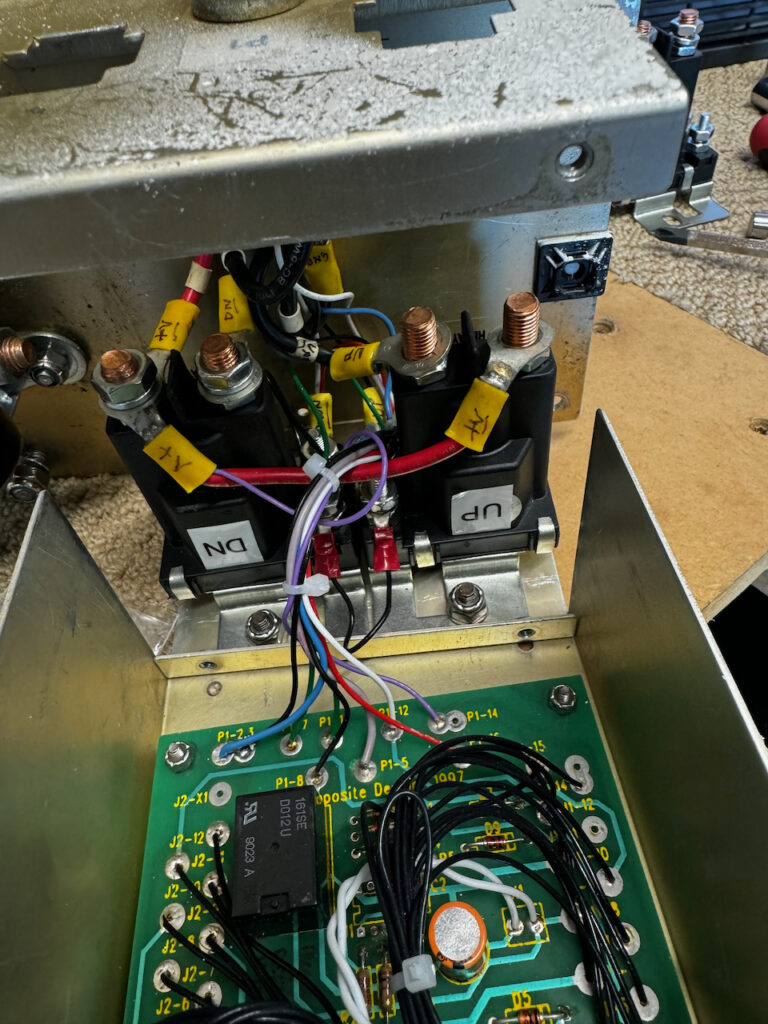

11/17/2023 - Retract Control System Upgrade

While the fuel pump was out for overhaul, I took the opportunity to send in the retract control system for an upgrade. This was recommended by Wayne Hall, the owner of Composite Design who built the “Gold Box” control system. I had a revision A of the box, and he said that there is a newer version whose components were a bit more reliable. It’s ironic, because we spent the next month going back and forth on issue with the new box when I got it back. It turns out that one of the solenoids was faulty, and would fail to close in the vertical orientation (the orientation in the aircraft). His tests did not see this since his testing right was oriented horizontally. Whew… it was one heck of a bug to track down, but we finally got is resolved. Thanks Wayne!

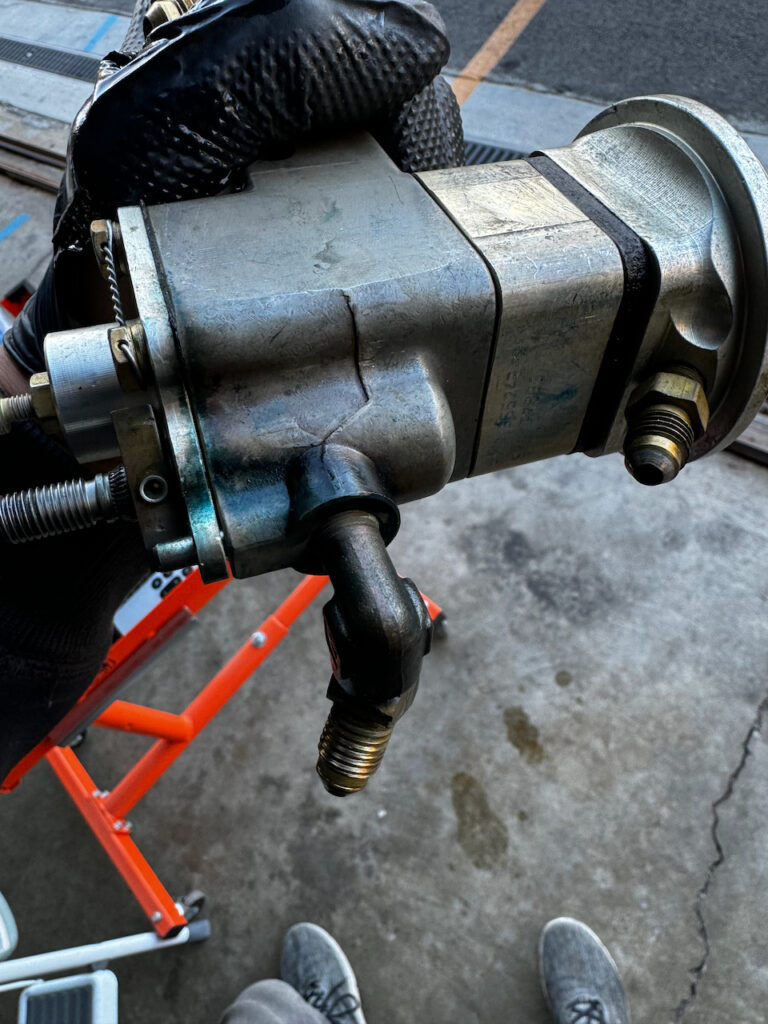

12/9/2023 - Nose Collapse and Repair

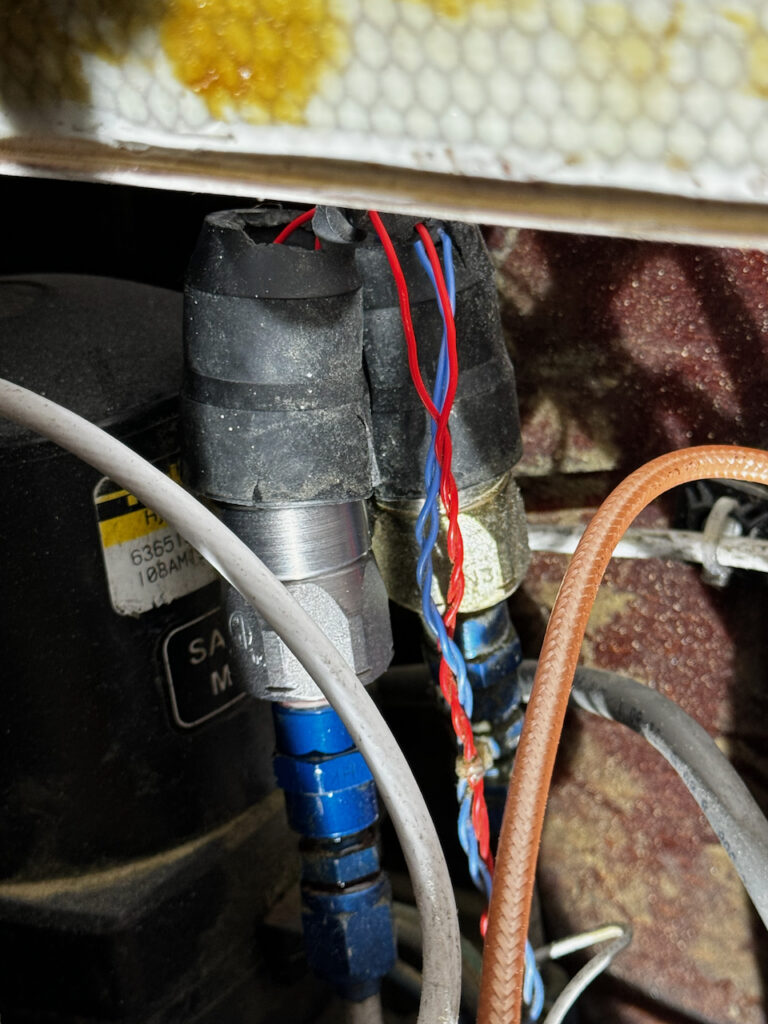

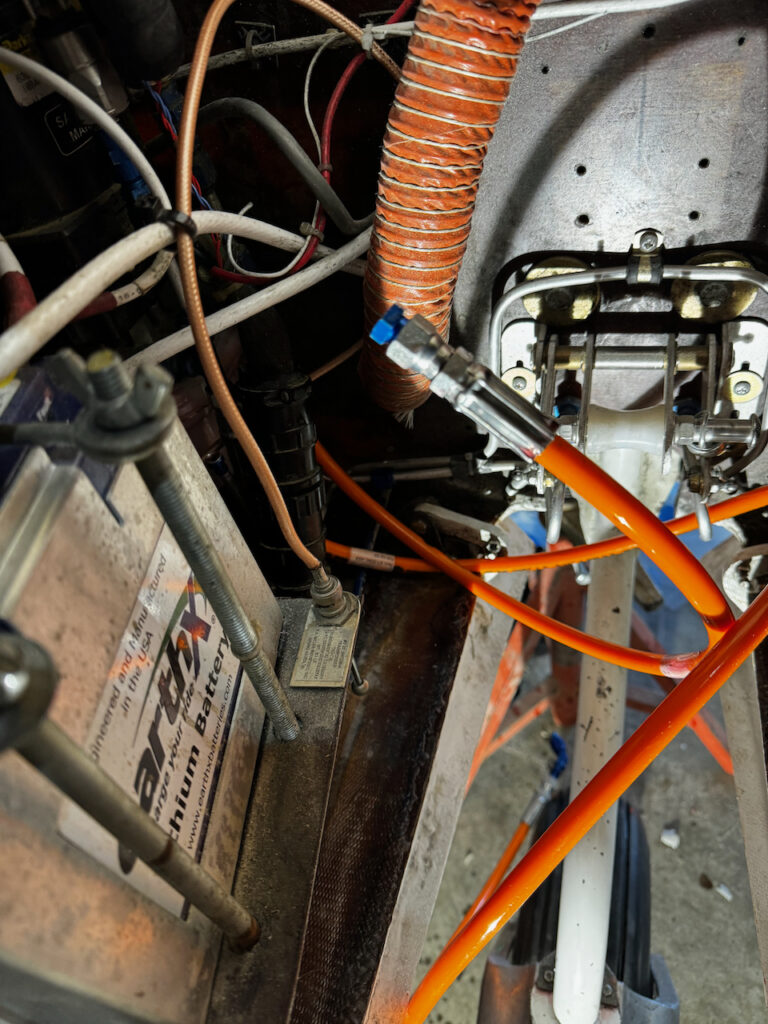

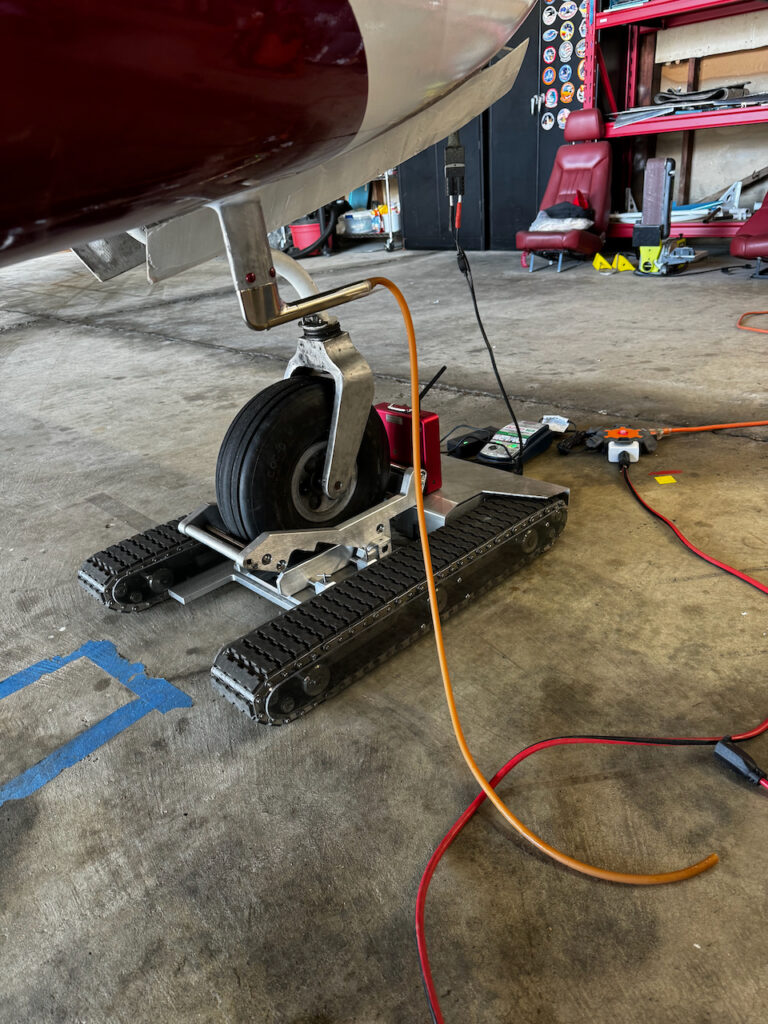

The saying that “There are two kinds of pilots. Those that have, and those that will have a landing gear failure” is very true. Thankfully, it wasn’t a pilot error issue, and a nose collapse on a canard is very minor. I had to replace the nose gear cylinder, and do some body work. Everything else was in fine shape. I took the opportunity to replace all the hydraulic lines to the nose gear cylinder and the bypass valve while I was in there, and I now know the landing gear system better than ever. Nothing like taking a whole system apart and putting it back together to gain confidence in how it works.

So what happened? As with many things, it was multiple failures adding up. The initial root cause was the down pressure switch had failed in the closed position, so the hydraulic system believed the down side was pressurized. That means when you put the gear switch in the down position nothing would happen. That’s ok… you’ve got a dump valve to let gravity set the gear in the over-center position. Well…. that’d didn’t quite work. The main gear came down no problem, but the nose gear did not over center. There is a gas spring that is supposed to help over center the joint, but in this case it was not effective. (On a side note, this is a known issue with excess drag in the nose gear geometry). I tried pulling Gs, wig-wagging the plane, etc. Nothing… nose gear light would not come on. The final option is a modification on the keel of the aircraft that allows for manual access to the overcenter joint with a wood dowel to force the gear to over-center (assuming the gear has come down most of the way). Unfortunately, this modification was not in my aircraft yet, and so I was out of options. I notified the tower of possible nose gear collapse on landing, and set up for a normal approach. On main gear touchdown, I pulled the mixture and lowered the nose. The nose came down soft and held for a couple seconds giving me hope, but alas, the gear slowly retracted into the wheel well resulting in a not so great scraping sound. A few moments later the aircraft came to rest and I hopped out. James and a couple others were already at the runway as I had called them in the air to notify them of the situation, so we rolled the aircraft off the runway and walked it back to the hangar to start the repairs. I’ll skip the details on the repair work, but it was long and slow. Most of the time was waiting for parts to come. Since I was learning on the go, it was a lot of individual orders as I realized what I needed.

On a side note, I have wondered deeply whether the work I did on this gold box had anything to do with the nose collapse. I don’t think so, but I’ll never know. What I do know was the morning of the collapse, I had put the aircraft on jacks and run through 5 nose gear cycles. All of them worked as expected, so I’m not sure there is much else I could have done to verify the system before flight.

After almost 3 months, everything was ready to go for flight tests. It was an exciting day, but in the end uneventful. The gear has been working flawlessly since, with probably over 100 cycles. Thanks to everyone that gave me moral and hands-on support through the whole ordeal. It was one of the best learning experiences (as a pilot and builder) I’ve every experienced.

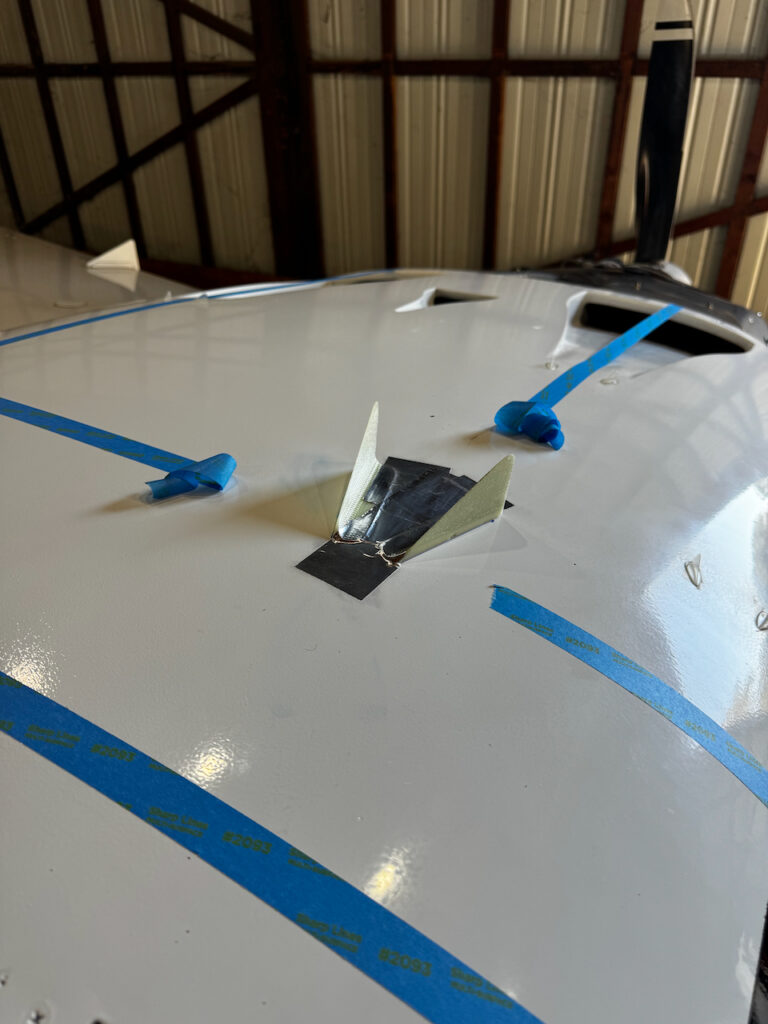

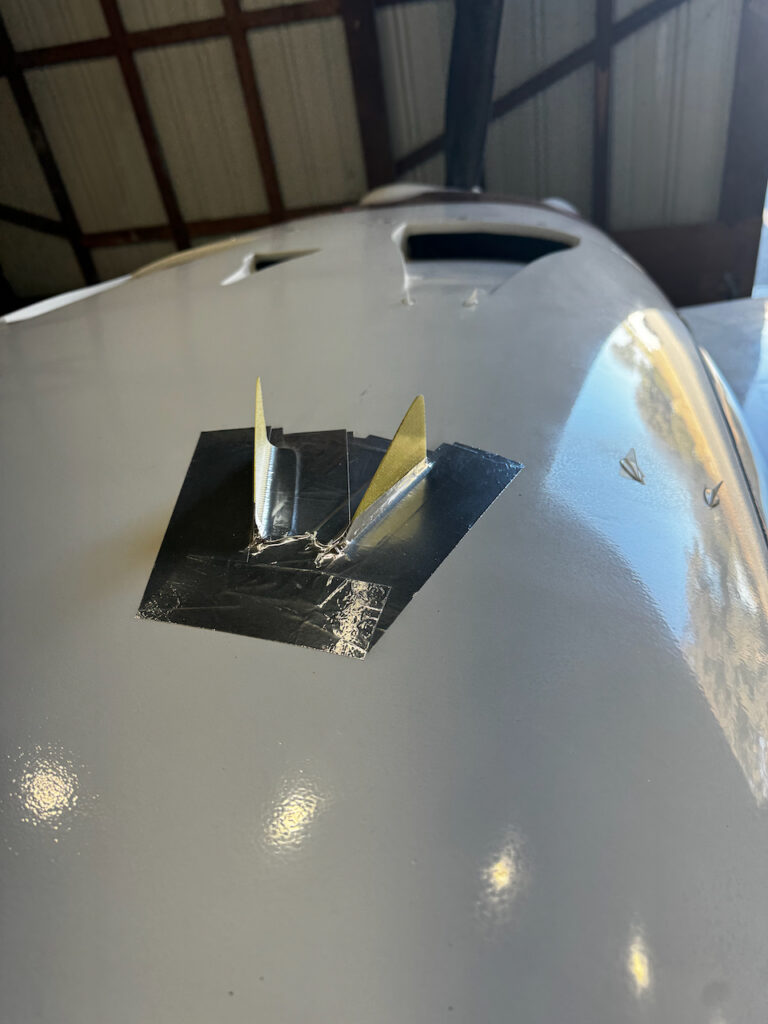

8/16/2024 - "Shark Fin" cooling

As with all air cooled piston aircraft, cooling the engine is a perpetual battle. It is an even bigger challenge with pusher aircraft that are “air flow challenged”. My engine is generally manageable, but on hot days it will creep into the low 400s on the CHT. I wanted to fight this with every option, and Riley at Velocity suggested trying the shark fin cooling VGs. The theory is that by disturbing the airflow in front of the NACA scoops, you can get a bit more air pushing into the scoops, and thus better cooling. Riley gave me instructions on how to layout the shark fin locations, and recommended I temporarily install with aluminum tape before permanently installing with silcone and a couple pop rivets. TLDR, it worked great and I’m seeing easily manageable CHT temps now. On the hottest of days I can keep all cylinders down below 390, and usually below 380 throughout the entire flight. This gives a lot of margin against the factory maximums. Cool. Literally.

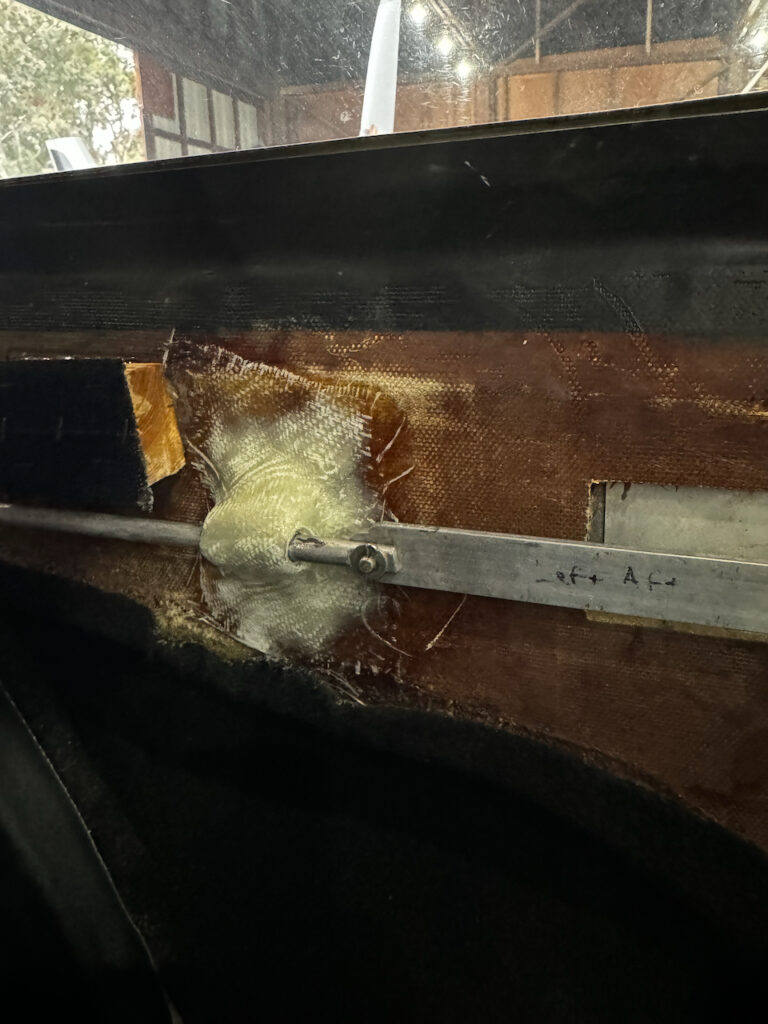

9/9/2024 - Pilot Side door latch rebuild

Quick note to be thorough on this one. I rebuilt the latching mechanism on the pilot side door. One of the pin anchor points had gotten floppy and closing the door became a pain. After cleaning up the old anchor point, it was quick build up of a new anchor and wrapping it in fiberglass. It took a few days waiting for each layer to dry, but now I’ve got a smooth door mechanism. So nice!

9/16/2024 - Annual Condition Inspection

Last month I went down to Tehachapi for this year’s condition inspection. Everything went smooth! I’ve got to give a quick shout out to Marc Zeitlin, my mechanic for the Condition Inspections. He’s now donen my prebuy, plus 3 condition inspections. He is very thorough (hundreds of items he checks), and always provides a ton of good feedback on keeping the plane in top shape. There are a list of lower priority items to get to (removal of sparrow strainer, secure some lines a bit more, etc), but overall Marc thinks the plane is in good shape. While I was there I did my first Saavy Borescpoe inspection… it is a set of 66 photos taken (11 of each cylinder) that you send into Saavy for analysis. I got my analysis back and everything is nominal. Nice! I will plan on doing that one a year going forward. It will be nice to build up a record of the cylinder condition.

So that’s it! An eventful year of upkeep, upgrades, and repairs on the Velocity. The plane has been flying wonderfully and I’ve just passed the 400 hour mark of flight time. I absolutely love this plane and hope to keep flying it for years to come! I’m thinking of bringing in a couple partners to make sure she keeps flying consistently. We’ll see what the new year brings. Until the next update.. Happy Flying!!

3 comments

super solid and impressive… making it sound straightforward… and going right after so many details in real time..pilots always seem so

damn competent, but this is next level…

Nice feedback. I have no doubt your plane is the best maintained on the West Coast if not the USA

You are a busy man, Paolo.