I’ll be honest, getting over the priming roadblock has opened up new energy for me. There have been a few of these for me. First was getting over the fear of working on actual parts. I found any reason to delay getting started. Second was getting past my first major mistake, the tie-down. Understanding that this build will not be perfect, and I will run into issues was daunting to me. After all, I will eventually be putting my life into the quality of the work, but the reality is, it’s impossible to get every task right the first time. It has to be ok to double back and try again. Priming is the next of these hurdles that created a mental block and slowed down my progress. The task was so foreign to me, I again avoided it for as long as I could. Once past it though, I’ve found a new energy to move forward. I’m guessing there will be lots of these along the way. No matter, off we go!

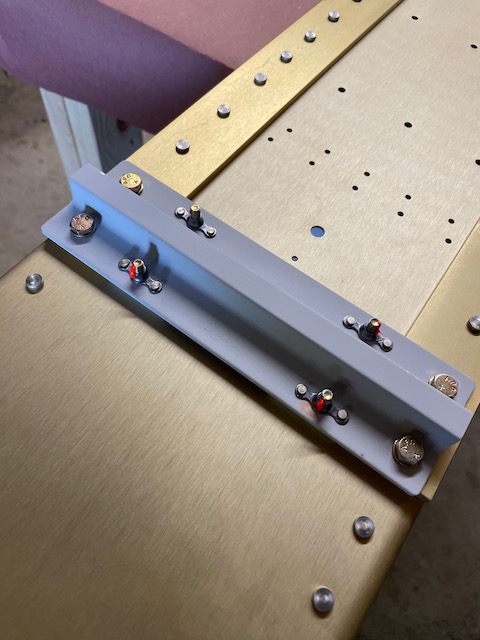

I decided to focus on the tie-downs since it was a relatively small project and I wanted to wrap up the 7-1 section. After a slight hiccup riveting one of the spacers incorrectly (and subsequently removing the rivets), I correctly riveted the spacer nutplates to the tiedown and then torqued the tie-down bolts (AN3-7A) and spacer bolts (AN3-6A).

Torquing the bolts required breaking out some new tools (and some old ones). The Torque screwdriver allows for settings of 10-90 in-lbs. In this case the recommended torque for AN3 bolts is between 20-25 in-lbs (not to be confused with ft-lbs!). This information can be found in Section 5 of the manual, page 5-20 (or like anything else, Vans Air Force forums!) Since my torque screwdriver only “locks in” on even numbers, I opted for 24 in-lbs. Its surprising how little force 24 in-lbs actually is. To ensure the nuts don’t back out, you apply a “cross check” torque seal which shows if the nuts start to back out.

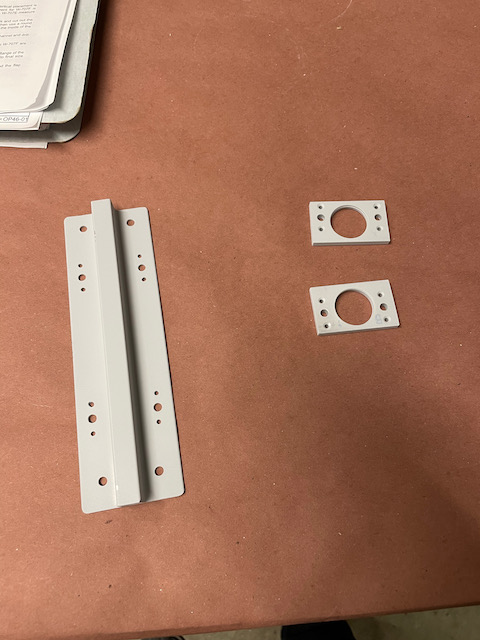

After torquing the first tie down, I got going on the replacement tie-down for the right main spar that arrived last night. It feels good to know if I mess a part up, Van’s has an easy way to get that part re-ordered and sent out. I guess they are used to us noobs! I’ll spare you the details, but checkout the clamping technique learned from previous mistakes. It went pretty fast, and within an hour I had the tiedown and spacers fabricated and drilled. Then it was clean up and head home to hang with the family.

Hopefully I can sneak in for another session this evening to work more on the tiedown, but otherwise, that’ll be the next task whenever I get back to it!

1 comment

Proud of you pushing through the mental block/fear. It must tremendously satisfactory, strong confidence building and allows for personal growth