Last post I alluded to a quick session Finn and I did to design a better fuselage stand. The reason for this was a couple issues I had with the current setup.

- Sawhorses were slight unstable. Given that many of the next activities will require climbing into the fuselage, I wanted to make sure there was a nice stable stand for the fuselage to rest on.

- Height was not quite right. Depending on what we are working on, it is nice to have the fuselage at different heights. Although this was possible with the saw horses, it required shimming up the fuselage, or doing a bit of work to adjust the height of the sawhorse itself.

- Inability to level the fuselage easily. Some of the future steps require accurate leveling of the fuselage (for example mounting the wings)

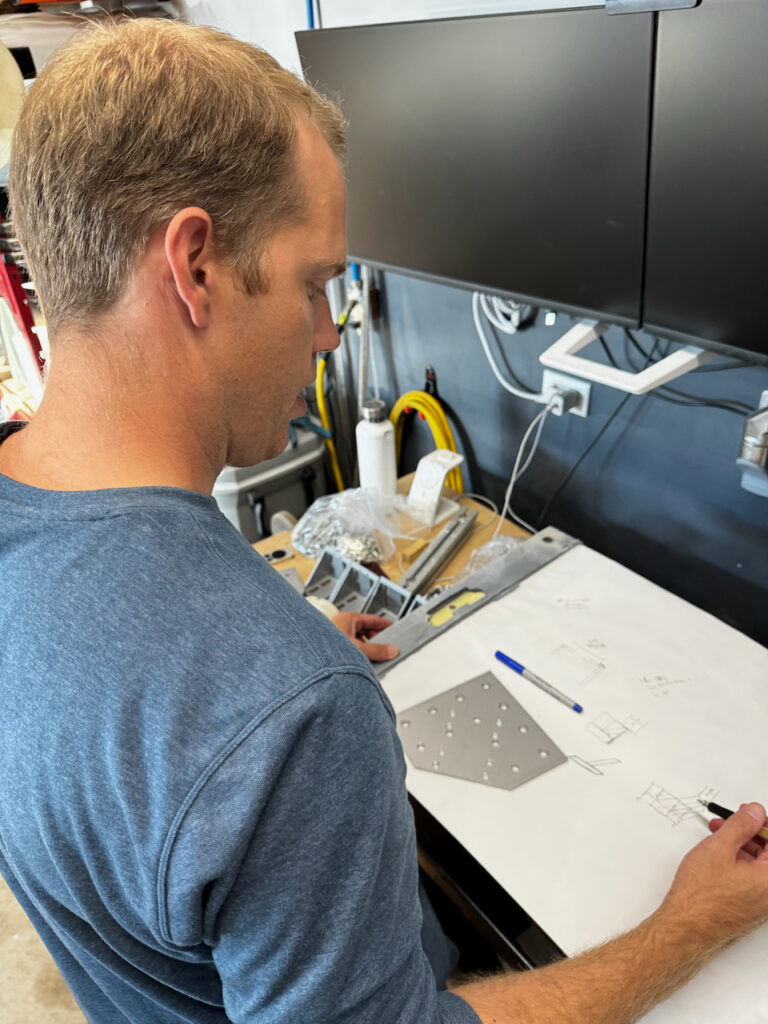

With these product improvements in mind, Finn and I designed a stand that solves these issues. Thankfully, we were able to reuse the 8020 aluminum from the wing stand structure, So no new material required. Todd and Brant came down to help me do the bulk of the assembly, then I finished up some of the details to provide an appropriately sized padded platform. All in all, it was a great 8-ish hour project that will pay dividends for months to come!

Most of my focus had been on the fuselage stand over the past week, but I did manage to get in a bit of riveting for the forward and aft seatbacks although still a lot to go on the aft one.

With the fuselage stand out of the way, and all the primed parts waiting to get squeezed, the next few sessions will be all about wrapping up the seat flooring section (as far as I can get before mounting the wings). There’s also a bit of work to be done on the velocity, so might be distracted for a bit. Until then…. Happy Building!

1 comment

Fantastic ground support equipment effort. Bravissimo keep on trucking.