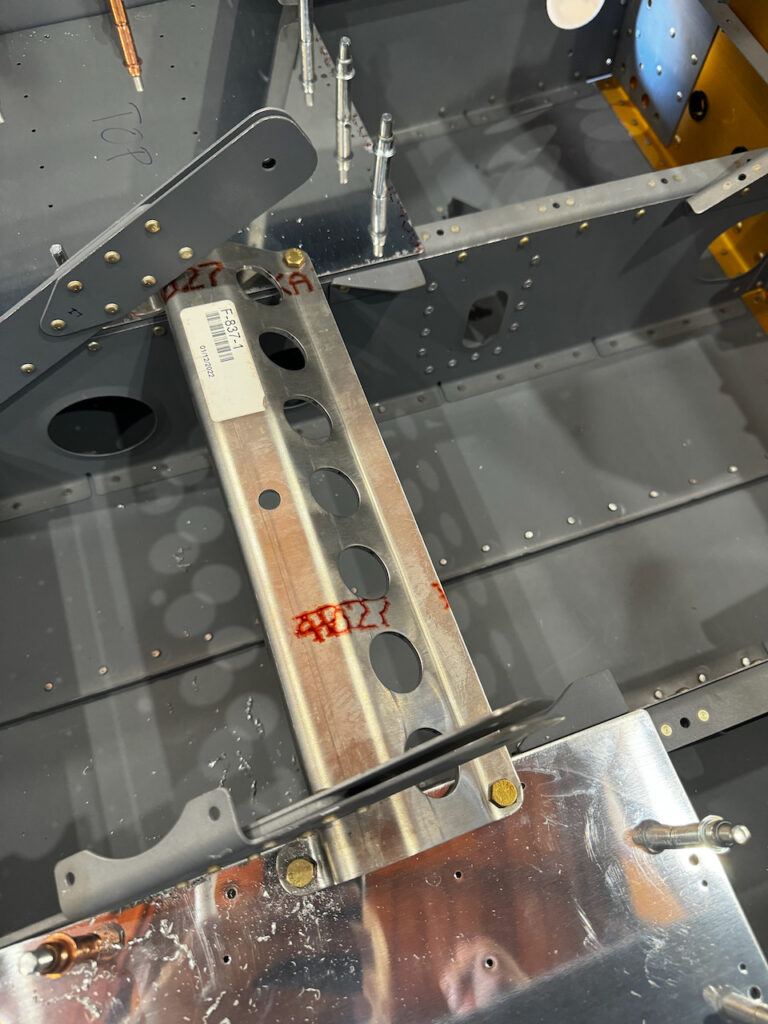

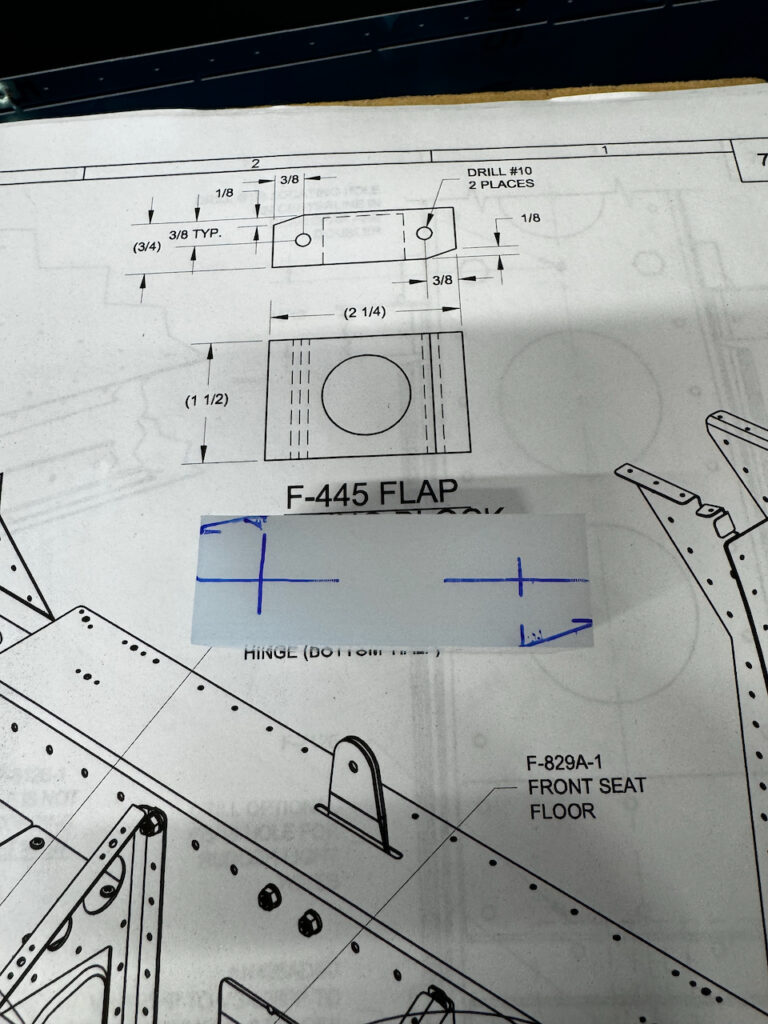

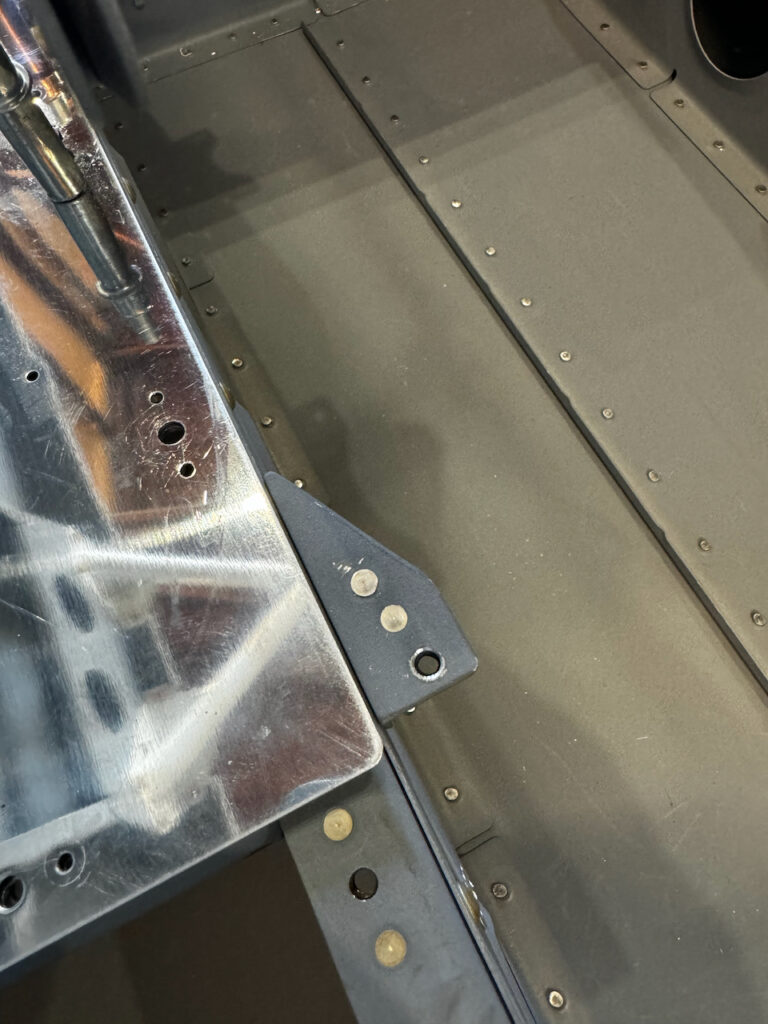

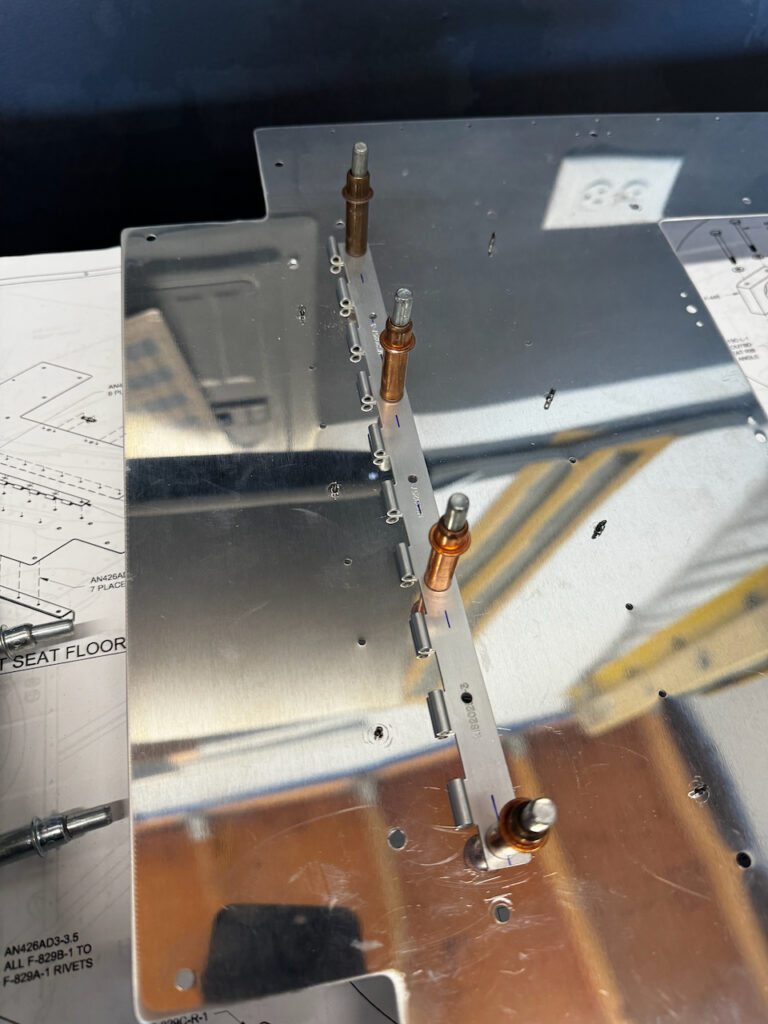

There was a lot to do to prepare the flooring for priming. Most of it was final drilling, deburring, and fitting, but there were a few challenging tasks. The biggest of which was the Flap Weldment Bracket fabrication. More to come on that later. There was also a bit of hinge fabrication for the front and back seats.

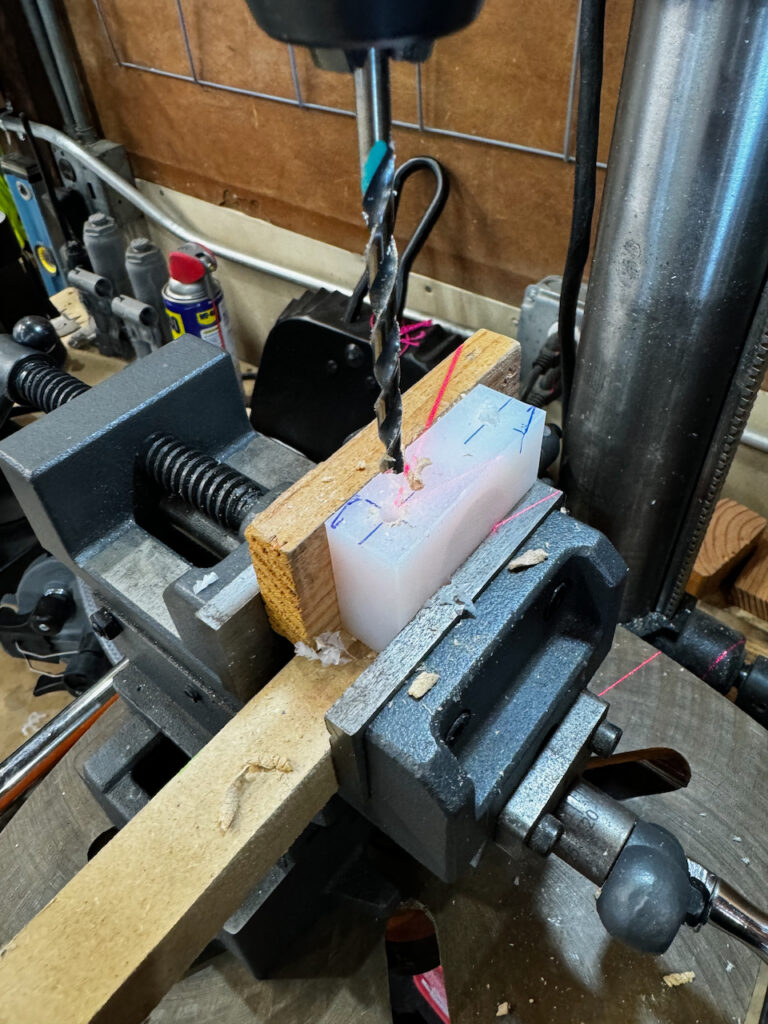

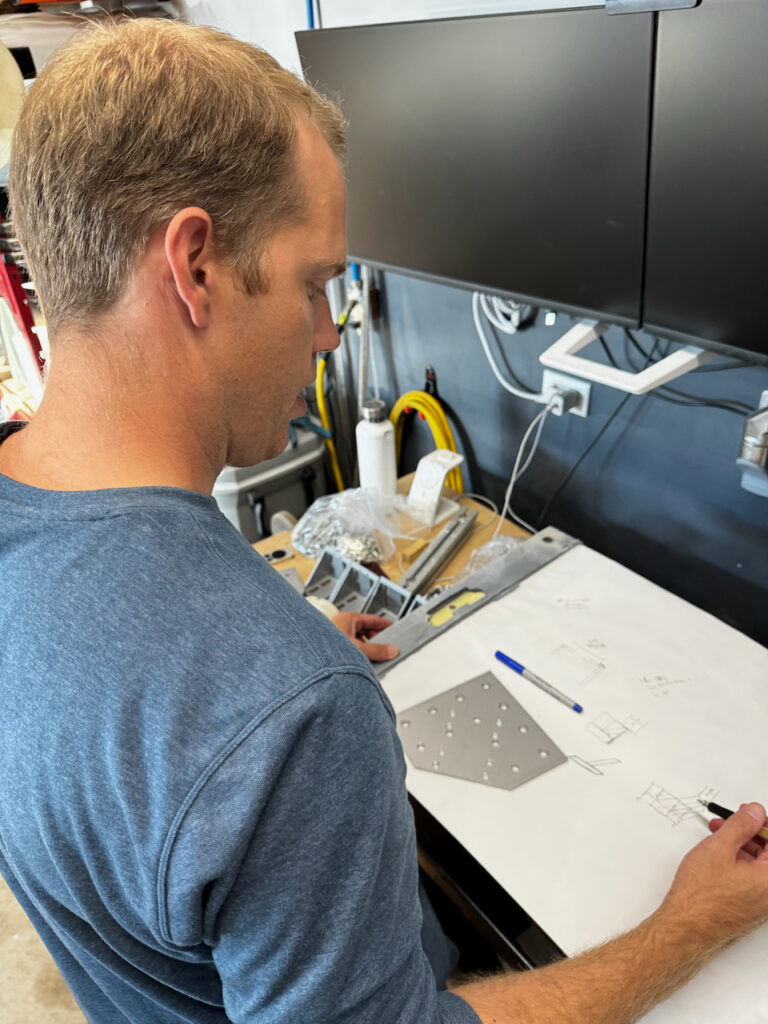

So speaking of the flap weldment fitment. The challenge is that the plans call for a very precise deep hole drilling of some fairly soft material. With my drill press, I found that the location I marked didn’t necessary match the location the hole came out on the other side. There wasn’t that much play in the tolerances of the holes once the flap weldment is in place, so getting these to line up were long and arduous. I ended up flipping the brackets upside down so that the hole adjacent the floor is more accurately positioned. Eventually I was able to get it done by tweaking the hole sizes to the attach nutplates a bit more than what plans called for.

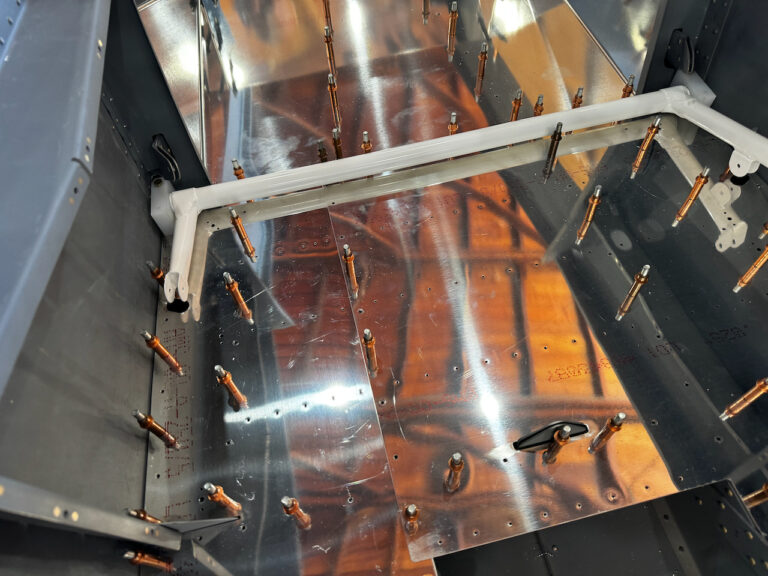

Outside of the flap weldment installation, most of the other prep work was fairly standard. A few pictures below.

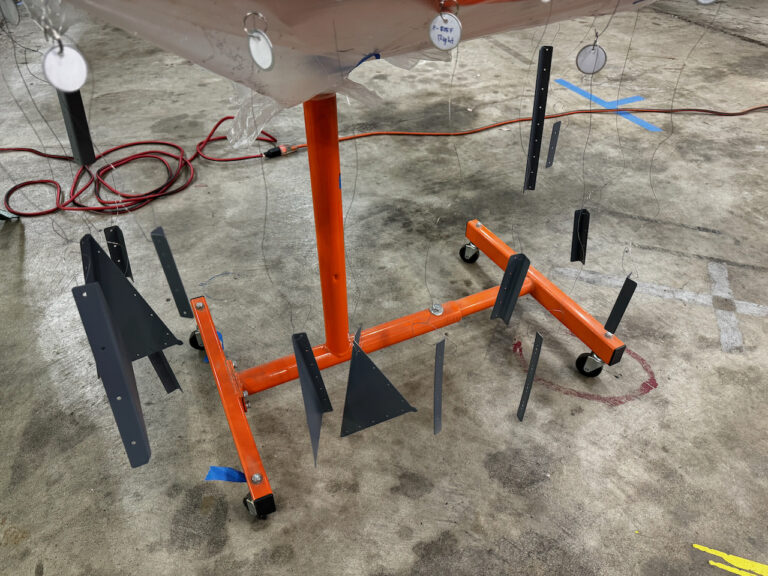

With parts prepped, Sam and I decided to get a Priming day snuck in at the end of the week. I decided to try an iteration of my “hanging parts” method for marking and spraying some of the smaller parts. In the end it didn’t quite work the way I wanted since I had to hold each part individually to avoid the parts from flying and spinning all over the place. We also attempted to use a new table surface for parts, but without the grating I usually use, the spraygun had a tendency to blow the parts over. Maybe I’ll perfect my priming technique by the time this plane is done… :D.

I always dread priming sessions… they are long days that inevitably end with a late night clean up. Glad this one is out of the way. Next step will be final assembly of the seatbacks, most of the flooring riveting, and wrapping up my side project that Finn helped me start of redesigning a fuselage stand. Then on to the seat ramps! Until then…. Happy Building!

2 comments

Progress!!!!!

Happy building. Lots of non fun tasks (priming) but it will be all worth it on the next step…. Great work