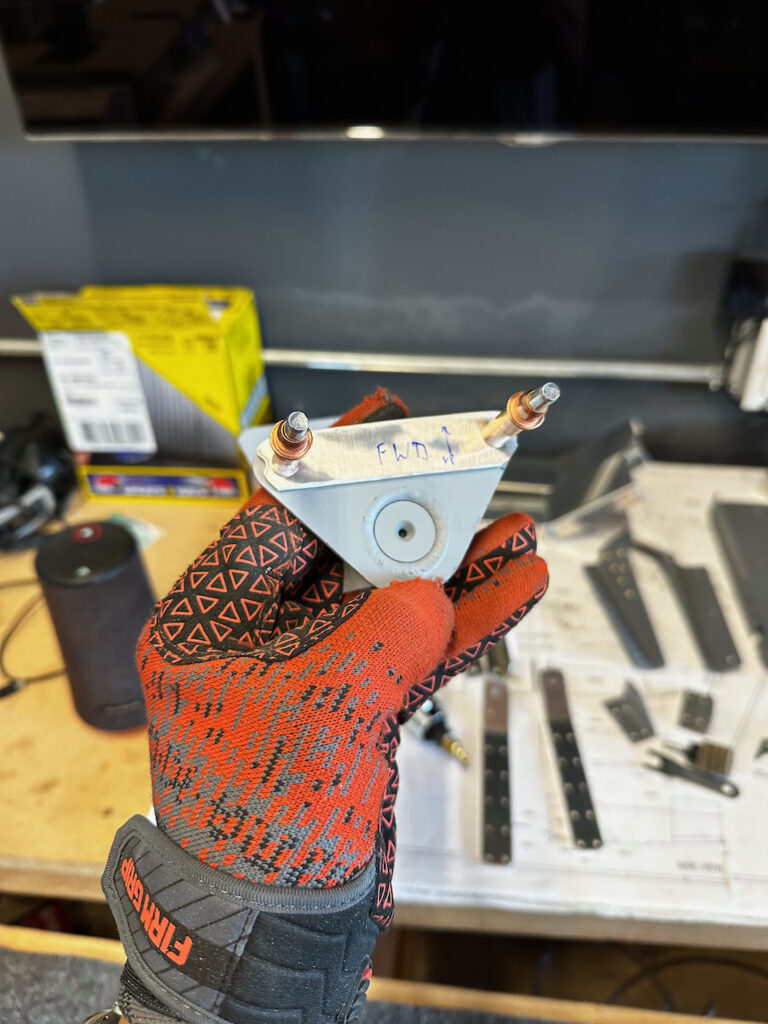

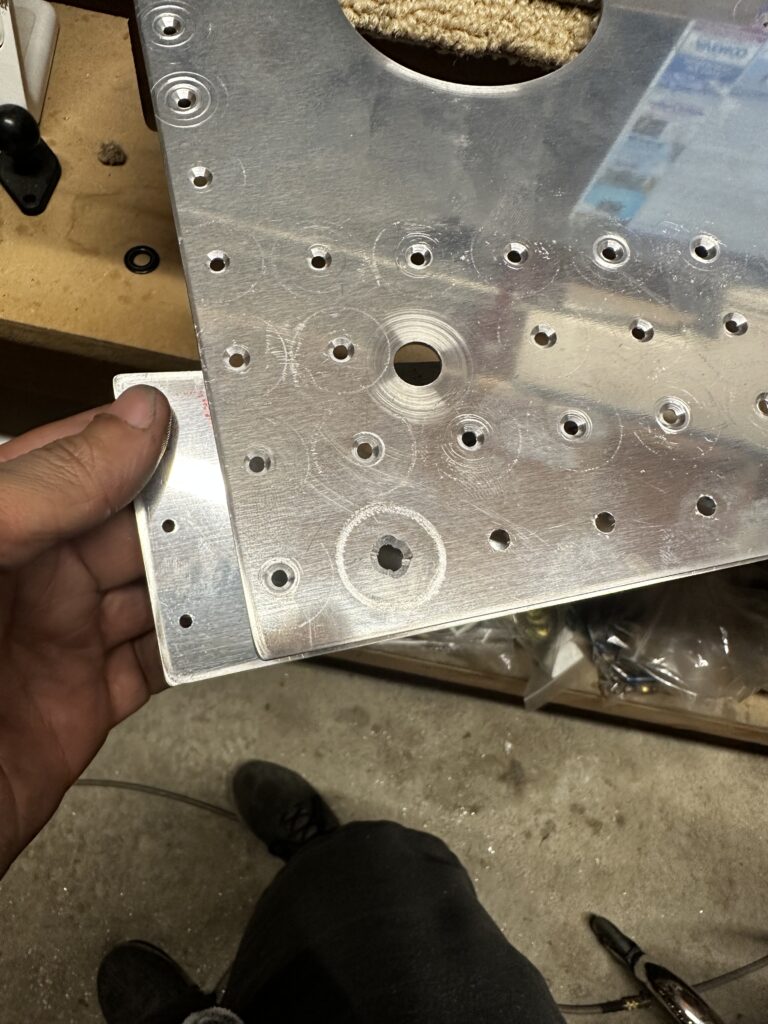

I know the post is a bit late, but better late than never. Before the Oshkosh trip (see below for detail!), I was able to get one last session in. The goal was to get as far along fuselage preparation as possible. With a bit of help from Sam and Alexander we were able to complete disassembly and start on the deburring. But before the assembly I needed to finalize a few items on the tail spring assembly. FIrst was an access hole for the tail spring nut. It calls for 3/4” final drill, so unibit it is! Second was the spacers. I wasn’t super happy with the plans call for 3/4×3/4 inch spacers. I decided to create a custom spacer of the right thickness and shape. I’m happy with the way it turned out, and should serve it’s purpose well.

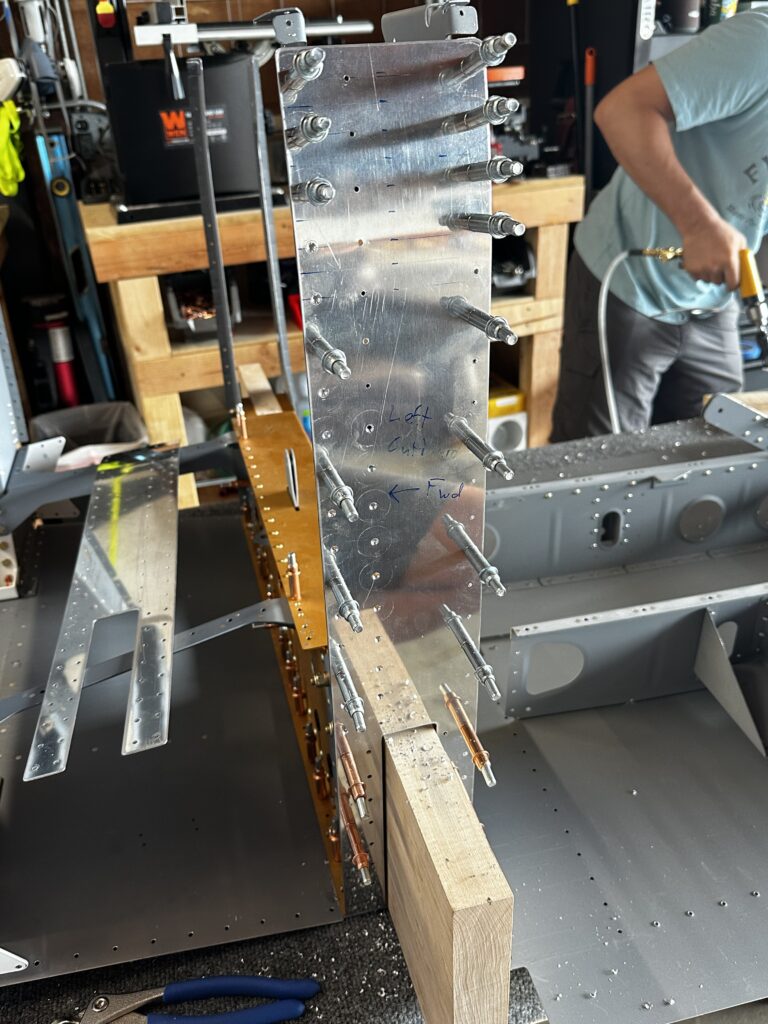

Final tasks complete, Sam and I spent the afternoon disassembling, then countersinking much of the thick metal. Later on in the day, Alexander started to debur the skins. He was able to tackle both sides of the largest aft side skins. Nothing special here… just grind through the work. one hole at a time.

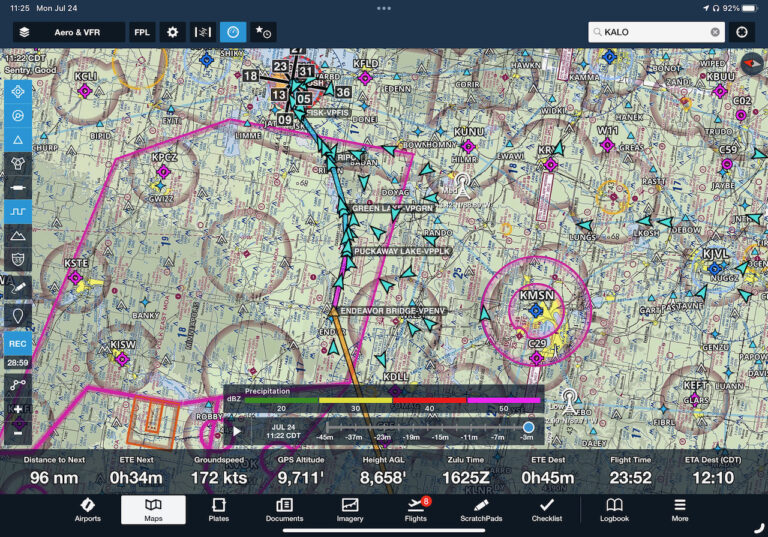

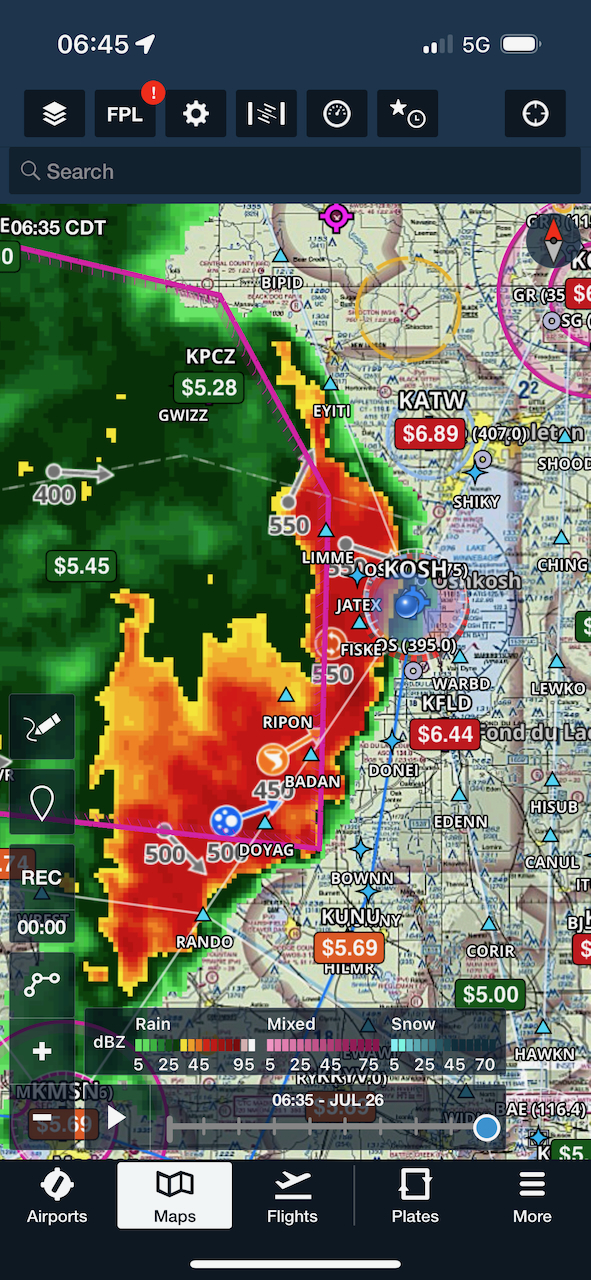

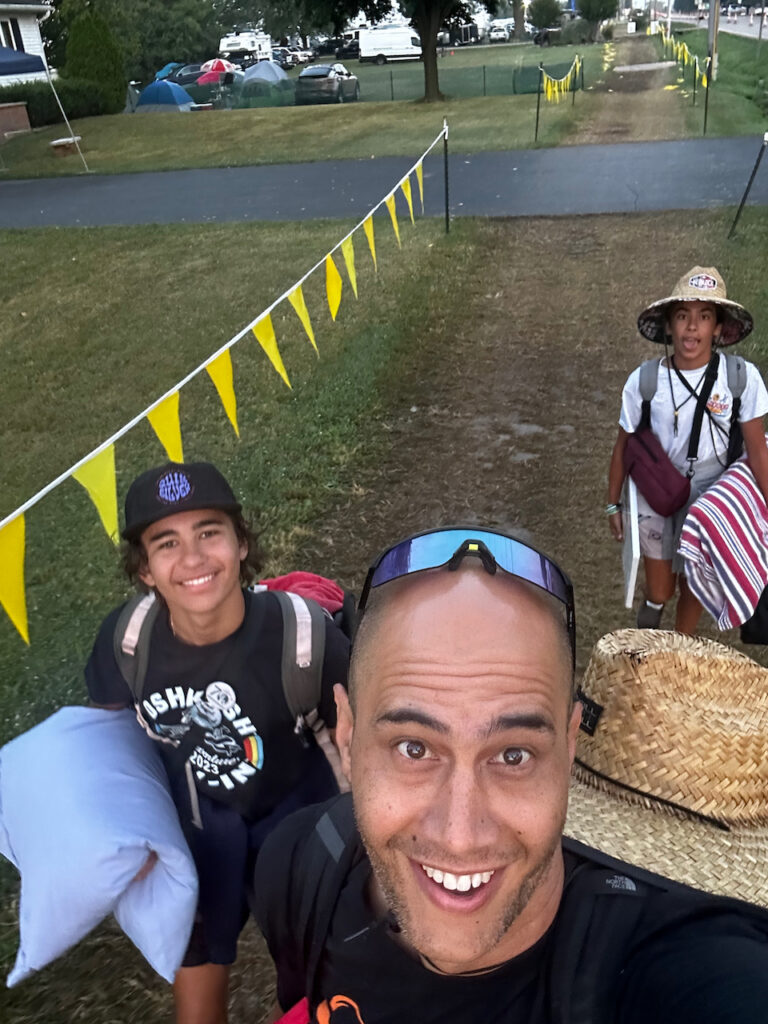

TLDR of Oshkosh, we had a complete blast, and as usual didn’t have enough time to see and do everything we wanted. We’ll go again next year. Maybe in the RV-8? NAH! Once back from Oshkosh (and then Europe trip), It’ll be back to the grind countersinking, dimpling, and final prep before priming and re-assembly. Until then, check out the photos from Oshkosh…. and Happy Building!

1 comment

What an adventure. Good progress in the plane. Congratulations