The largest storm of the year came through over the weekend, and essentially killed our plans for heading up to the mountains. The mountain pass has been closed for 3 days and counting, and my friends who live up there said the area is essentially fully shutdown. We decided not to wait it out, and headed back down to the bay for a “stay-cation”. Although I’m sad I wasn’t going to get some skiing in, I plan to fully take advantage of the unexpected build time this week. It started off with tackling a build problem I’ve been choosing to ignore for some time now.

Temp Control for Fuel Tank Sealing

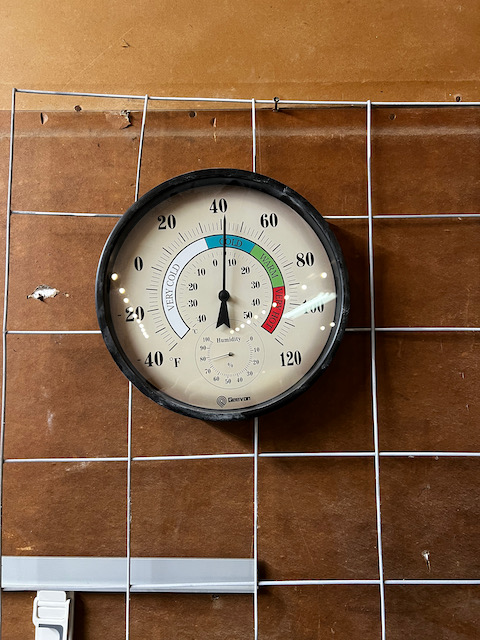

You read it right (in the image above). It’s 41˚F in the hangar. And that’s at 1pm. I know it’s not a Michigan winter, but for California, it’s pretty cold. In reality I could survive the cold while building (and have been up until now), but I’m pretty close to starting work with “Pro-Seal”, a specific sealant used for fuel tanks. It requires a certain temperature for ideal working time and viscosity. The data sheet says 70˚ and 50% humidity. While I don’t think I need to get to that exact condition, I’m fairly confident 41˚ will not cut it. So how do I heat a huge, old, drafty hangar to 70˚?? Well…I don’t! I needed to find a way to heat a much smaller area, and trap that heat so that I can seal the tanks in ideal conditions. Scouring the internet I think I found a solution…a portable greenhouse!

Sure enough, Amazon had about a dozen options, and I opted for a 6’x8′ portable greenhouse from Eagle Peak. It wasn’t ridiculously expensive, it gave me a enough room to fit the workbenches (in theory), and should retain heat. I received it a few weeks ago, and it was finally time to test it out. Luckily we had a portable electric space heater at home we aren’t using, so I brought that down and proceeded to set up the greenhouse. It would have been much easier with 2 people, but I wrestled my way through it and finally got it set up. With a bit of musical chairs, I was able to get the workbenches inside, and start the temp control test.

With the greenhouse setup, I turned on the space heater and started the long wait. Would it get heated up enough? Read on to find out…;). In the meantime, I had some time to kill and the greenhouse heated up, so I thought I’d pull out another side project I’d been wanting to do to for a while… Kaizen foam!

What the heck is Kaizen foam?

You know those super type-A personalities in your life? Can you imagine what their toolbox organization might look like? Probably something like this:

Well, turns out I’m one of those types, and have always wanted a toolbox that is organized with this level of beauty and order. To achieve that, you need a type of foam that allows you to easily cut and customize the foam, while still holding rigidity and shape over time. There are a lot of brands out there, and Kaizen Foam is one of those brands. The idea is, after cutting the sheet to fit your tool drawer, you layout the tools on the foam and use a special thin nose marker to trace their outline. Then, using a special razor, you can cut to a specific depth, and tear out the foam in a perfect trace of the tool. The trick is in how they construct the foam in thin layers so that once you have a trace it is fairly easy to peel off the foam with your fingers to the depth you cut. There are a ton of great YouTube videos on how to do this and at the end of this post I embed the one I liked the best. Below are some photos of the Kaizen foam project. As you can imagine, this takes quite some time to do, and I will continue on the project as I have time. Hopefully this week I can finish out the first drawer, but don’t want this to take too much time away from building the plane. Once the wing is done, and I’m waiting for the fuselage, I’m going to TOTALLY nerd out on this project!

So a couple hours later…how was the temp in the Greenhouse? 61˚F! And honestly, it felt warmer than that. I had the thermometer in the furthest corner from the space heater so I’m pretty sure the average temp was above 65˚. Now that I’ve got my solution for sealing the tanks, It’s back to prep work before sealing beings! Until next time, Happy Building!

2 comments

Wowww. What a great idea. A greenhouse. Creativity above all. That foam looks very interesting. A case for transporting Wine bottle from overseas might be an interesting project.

Sorry about the skiing. Next months there will plenty is great snow. 🤗