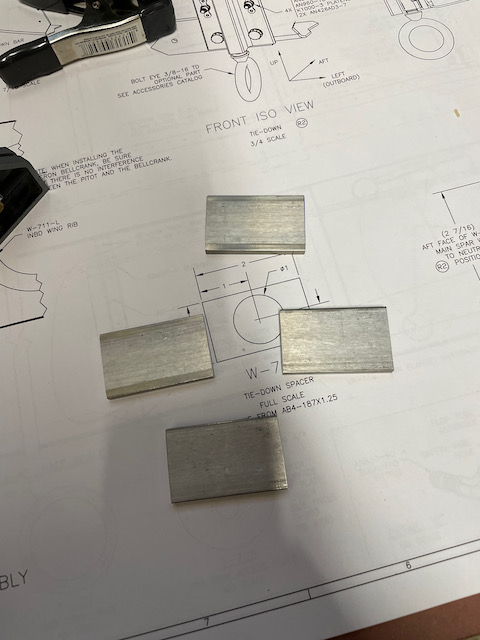

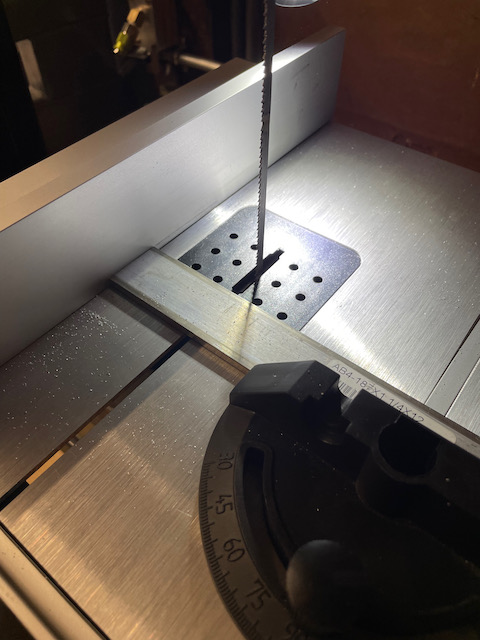

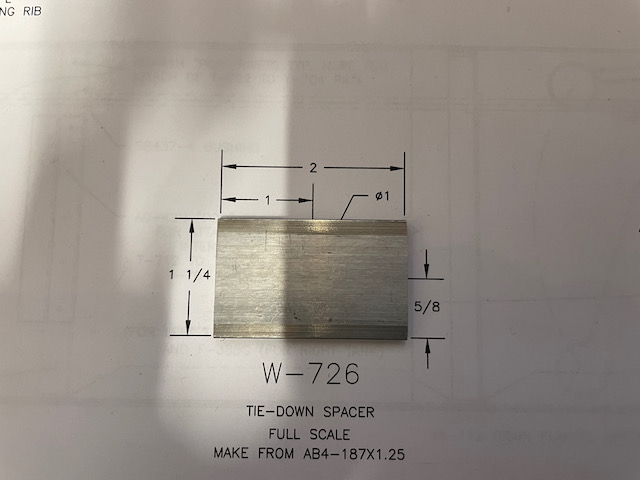

Tonight I started the fabrication of the W-726 tie-down spacers. The cutting was relatively straight foward, but having read in some forums about band saws, I learned that the stock blade is typically pretty bad. I noticed this already, so had ordered a Lenox blade. It’s much thinner, and could tell visibly it’s better quality.

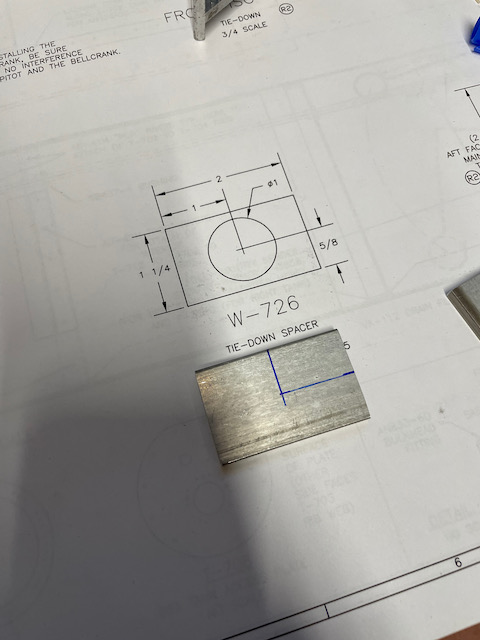

After deciphering what material I needed to use (hint hint, it is on the plan page DWG-15A, and it is AB4-187X1 1/4X12) I got to work. For the first cut I started measuring the dimensions as laid out in the plans, until I realized it’s a full scale plan, so I just overlaid the material and marked the lengths. After setting the bandsaw guides, I was able to cut the four pieces relatively fast, and a quick grind session cleaned up the cut.

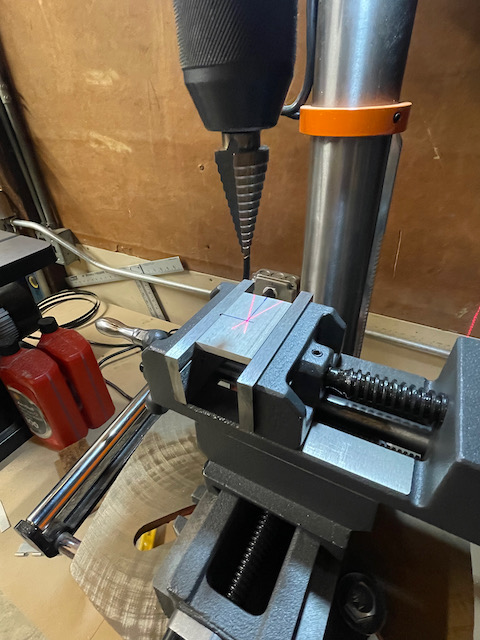

Next up was marking and drilling the lightening holes. These are 1-inch cutouts centered on the part. I used the plans again to mark the location, and then used my new cross vice to prep for drilling with a uni-bit. Unfortunately I ran out of time, so everything is prepped for my next session.

I’m still waiting on the tiedown material to come (shipment is severely delayed due to FedEx issues, so after I complete the holes, it may be on to the rear spar prep.

1 comment

Wowww. That’s a lot of work and a lot of “learning”. Congratulations