Today was a touch up day for the empennage. The only major task was connecting the trim tab to the left elevator. Weston, another one of the Synergy techs, had a great technique that wasn’t exactly how the plans specified attaching it.

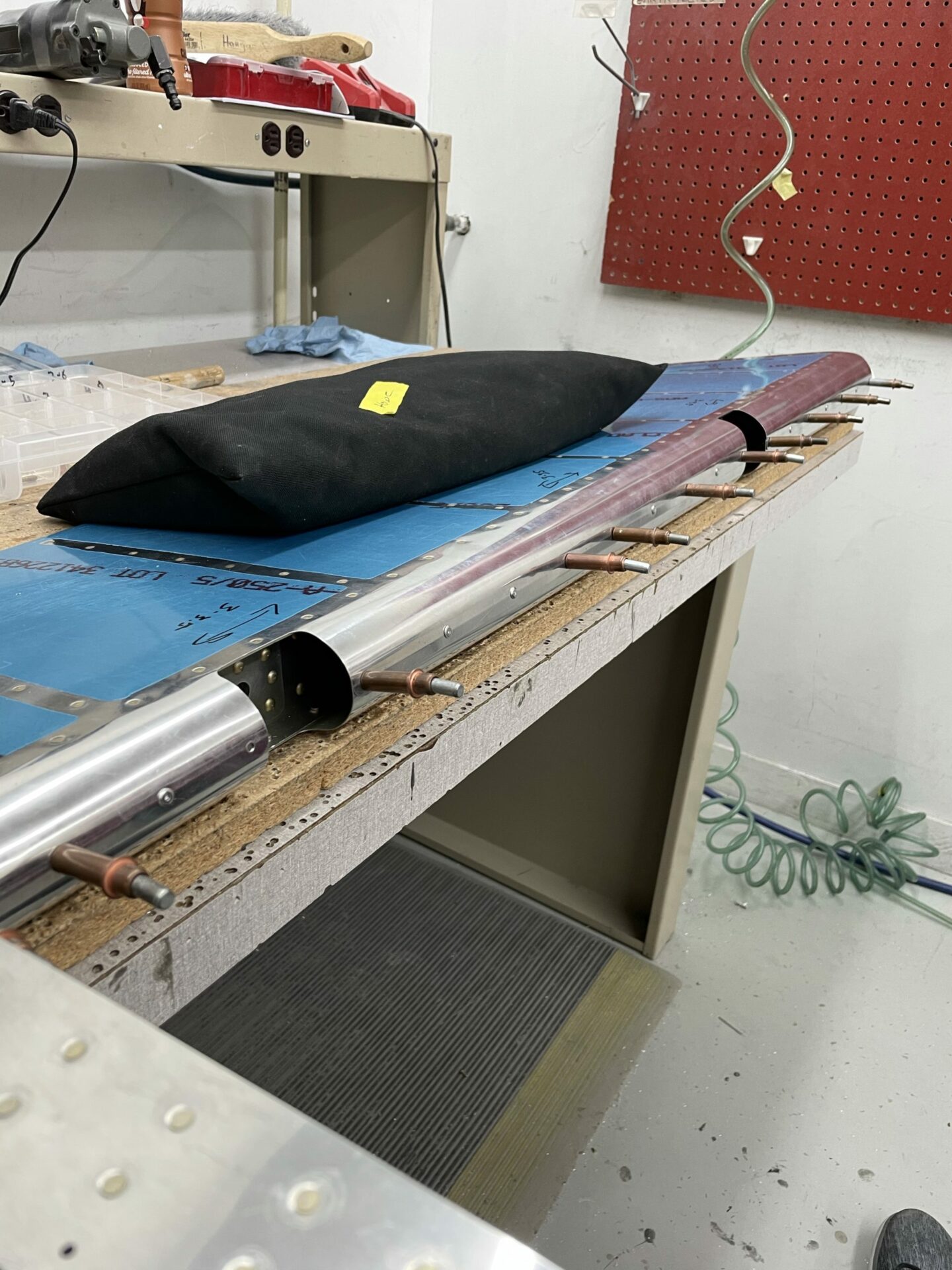

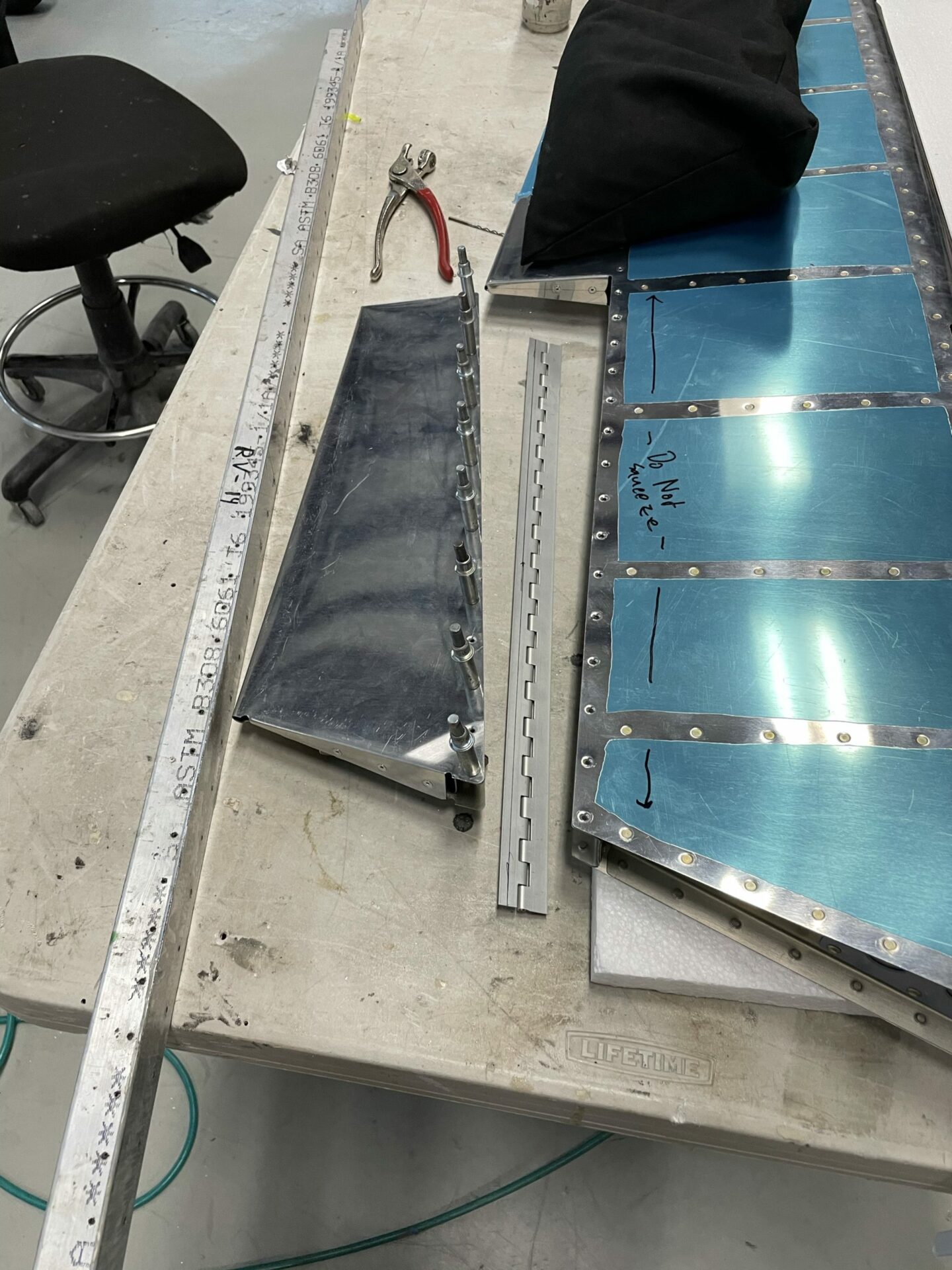

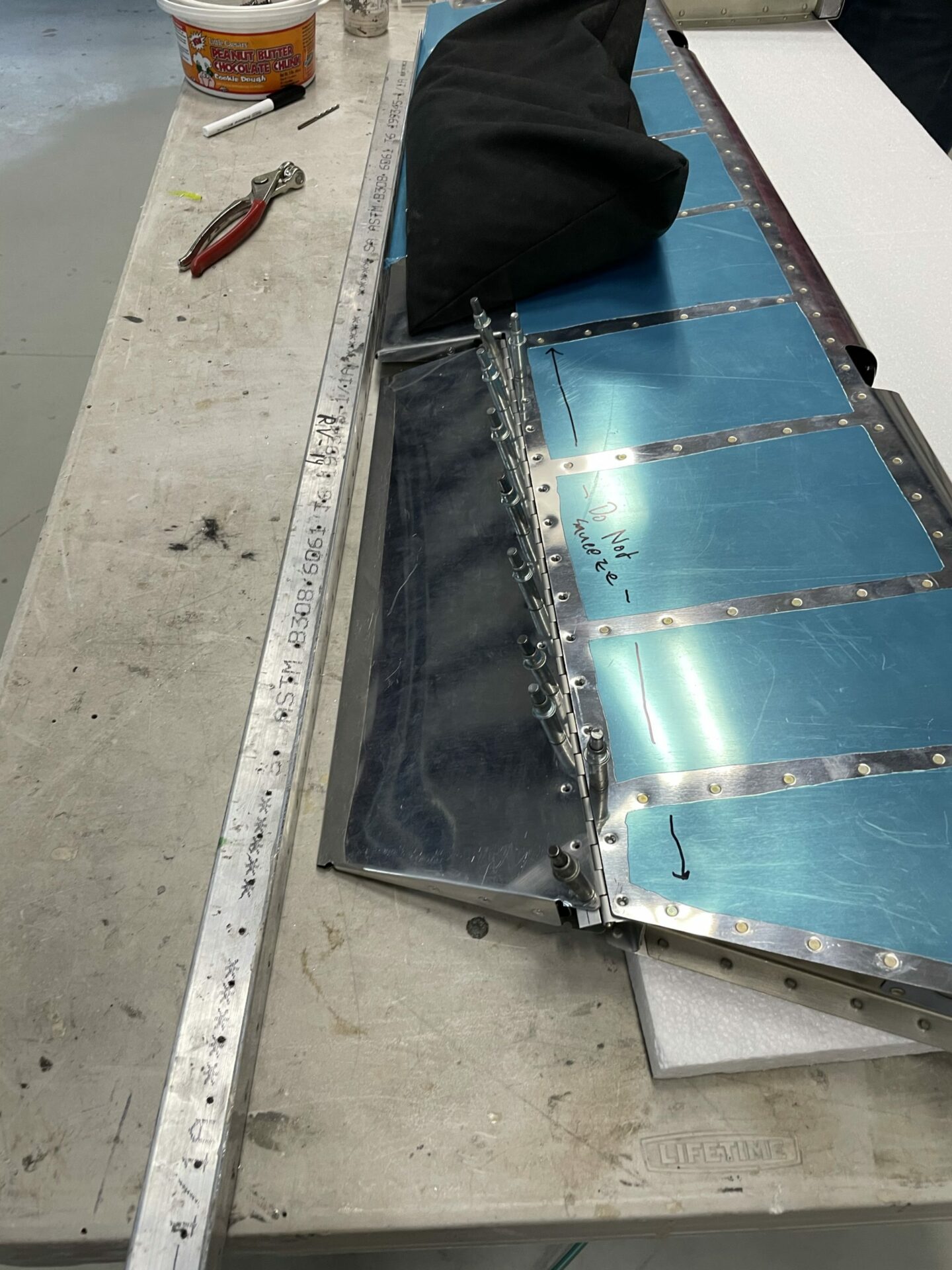

The goal is to ensure once attached the trim tab geometrically looks aligned with the elevator. Using a long angle bracket we could align the trailing edges of the two control surfaces while doing an initial marking of the trim side piano hinge. The goal is to get the hinge to be centered while being connected at the right location to geometrically work. Remember to verify the hinge is moving smoothly between each step to ensure you haven’t tweaked the alignment.

After the trim tab was fully cleco’d up, Next was aligning the elevator side hinge, and marking a couple holes. Once a couple clecos were marked and verified, I was able to mark the remaining holes and snap punch, drill, deburr, dimple and flush riveted the hinge on.

Note that after dimpling, the piano hinge was no longer smooth. This is due to warping and bending that occurs during dimpling. The good news for me was that Synergy had a “stretcher” and “compressor” machine that got a lot of the kinks out. It wasn’t fully smooth again until the rivets were pressed, but then it was smooth as butter!

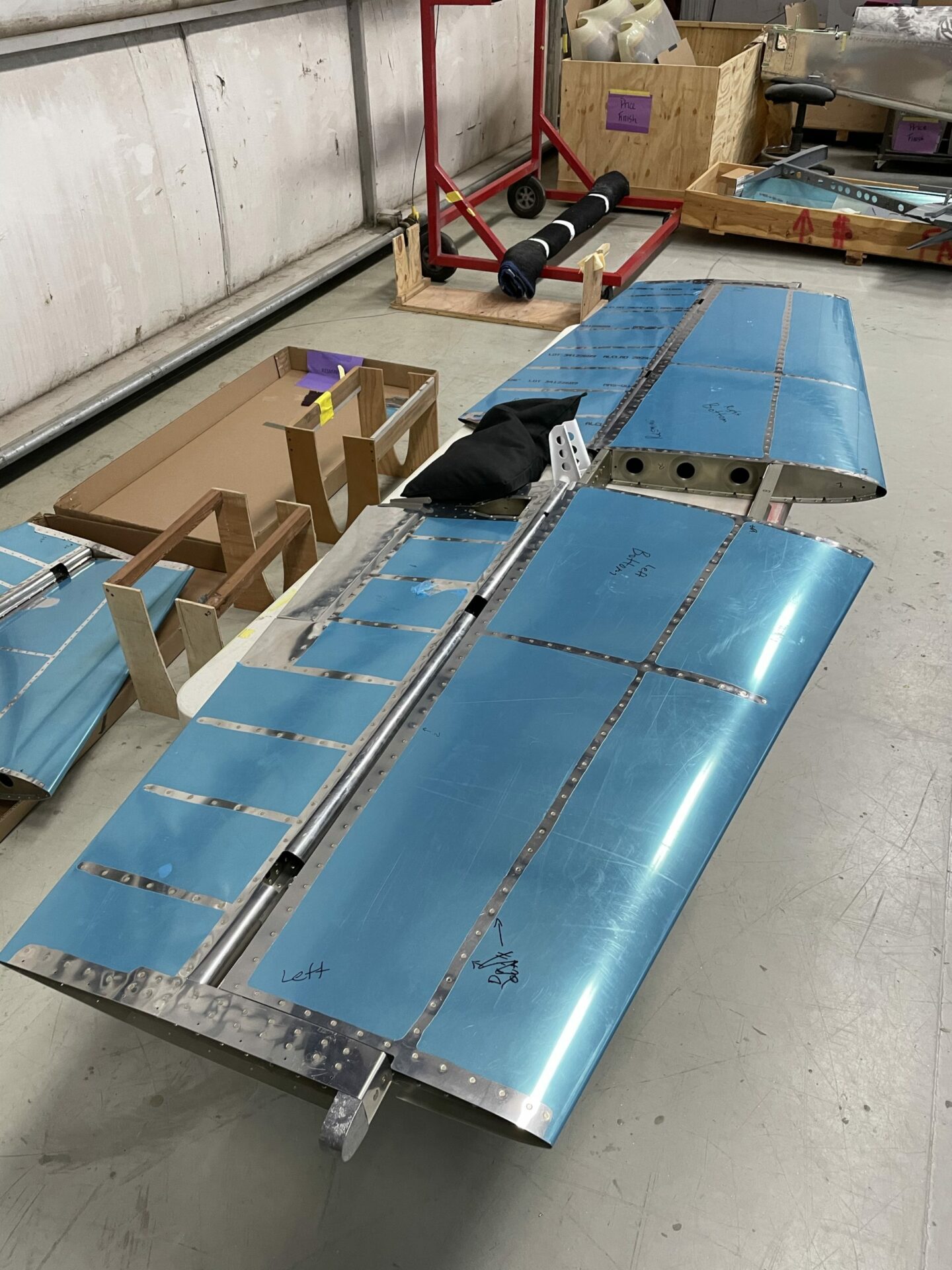

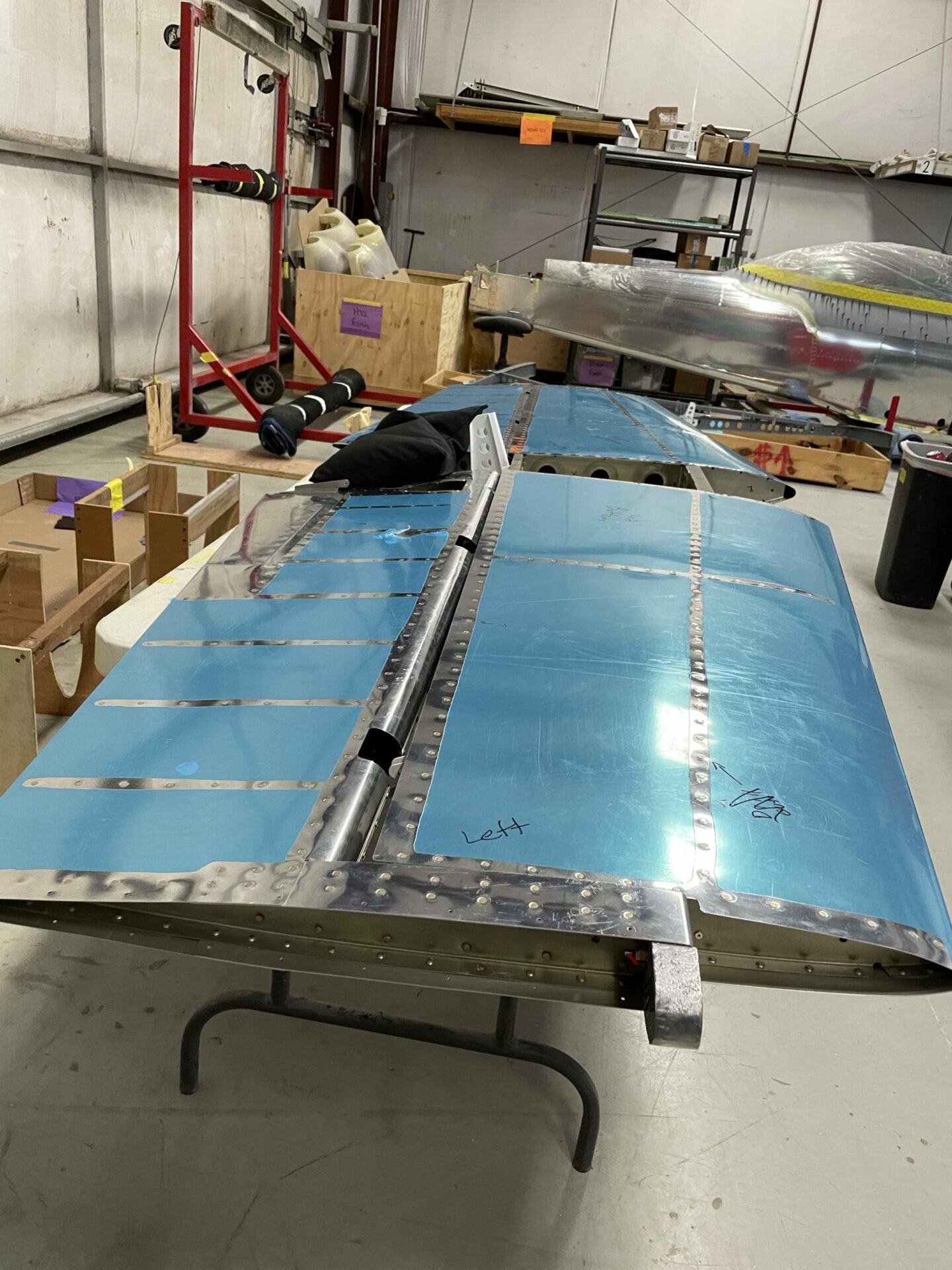

The other big activity of the day was rolling all the leading edges of the elevators and rudder. Since this is a one time task, and very awkward, Taylor did the brunt of the work, and I supported as needed. It is very much an art form. The main takeaway I noticed was the he initially over rolled the metal, and then pulled back edge appropriately so that there was still a lot of pressure between the two pieces.

Other tasks for the day were torquing down the counterweights, cleaning up some markings no longer needed (denatured alcohol in a ketchup squeeze bottle!) and taking the celebratory victory lap of photos to capture the success of the week.